A lip channel is a type of structural steel channel that features a “lip” along its edges. This design adds additional strength and stability, making it ideal for various applications, especially in roofing. The dimensions of 300x96x20mm indicate that the channel is 300mm wide, 96mm deep, and has a lip of 20mm, making it not only strong but also versatile.

Singapore Specialized Engineering Pte ltd

Category: Roofing

High Tensile 275x75x20mm Galvanized Lip Channel For Roofing

A galvanized lip channel is a type of structural steel channel that has been coated with a layer of zinc to prevent rust and corrosion. The dimensions 275x75x20mm refer to the width, height, and flange thickness of the channel, making it a robust option for various construction applications, particularly roofing.

High Tensile 250x75x20mm Galvanized Lip Channel For Roofing

A lip channel is a structural component often used in construction. It features a “lip” on one side, which provides additional support and makes it easier to connect various parts of a structure. The 250x75x20mm dimensions indicate the channel’s width, height, and thickness, respectively, making it a versatile option for a variety of roofing applications.

High Tensile 200x75x16mm Galvanized Lip Channel For Roofing

A galvanized lip channel is a structural steel channel that has been coated with a layer of zinc to prevent corrosion. The 200x75x16mm dimensions refer to the height, width, and thickness of the channel, making it a robust choice for various roofing applications. The “lip” refers to the slight protrusion or edge that adds strength and stability, enabling it to support more weight and withstand environmental stresses.

High Tensile 175x75x16mm Galvanized Lip Channel For Roofing

When it comes to roofing materials, the High Tensile 175x75x16mm Galvanized Lip Channel stands out as a superior choice for both residential and commercial applications. Known for its exceptional strength and durability, this roofing solution is increasingly becoming the go-to option for builders and contractors alike. In this blog post, we will explore the benefits of using galvanized lip channels in roofing, their specifications, and why they are essential for your next project.

High Tensile 150x65x15mm Galvanized Lip Channel For Roofing

A galvanized lip channel is a type of structural steel channel that has been coated with a layer of zinc to prevent corrosion. The “lip” refers to the flanged edges of the channel, which provide additional support and stability. The dimensions of 150x65x15mm indicate the height, width, and thickness of the channel, making it a versatile choice for various applications.

High Tensile 125x50x15mm Galvanized Lip Channel For Roofing

A galvanized lip channel is a type of structural steel that is coated with a layer of zinc to protect it from corrosion. The lip channel shape features a “lip” or flange that adds extra stability and support. The dimensions 125x50x15mm refer to the width, height, and thickness of the channel, respectively.

High Tensile 100x50x15mm Galvanized Lip Channel For Roofing

A galvanized lip channel is a type of steel channel that has undergone a galvanization process, making it resistant to corrosion and rust. The dimensions 100x50x15mm refer to the width, height, and lip length respectively, making it a versatile option for various roofing applications.

High Tensile 75x45x15mm Galvanized Lip Channel For Roofing

A lip channel is a type of structural steel channel that features a “lip” at the edges, which provides additional support and stability. This specific channel size—75mm x 45mm x 15mm—makes it ideal for a variety of applications, particularly in roofing systems. The galvanized finish adds a layer of protection against corrosion, ensuring that the channel can withstand harsh environmental conditions.

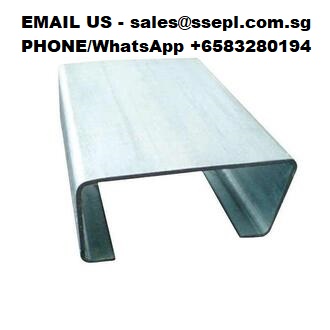

High Tensile Galvanized Lip Channel For Roofing

High tensile galvanized lip channel is a type of structural steel channel that has been coated with a layer of zinc to enhance its resistance to corrosion. This unique combination of high tensile strength and galvanization makes it ideal for use in roofing systems, where durability and long-lasting performance are essential.